Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

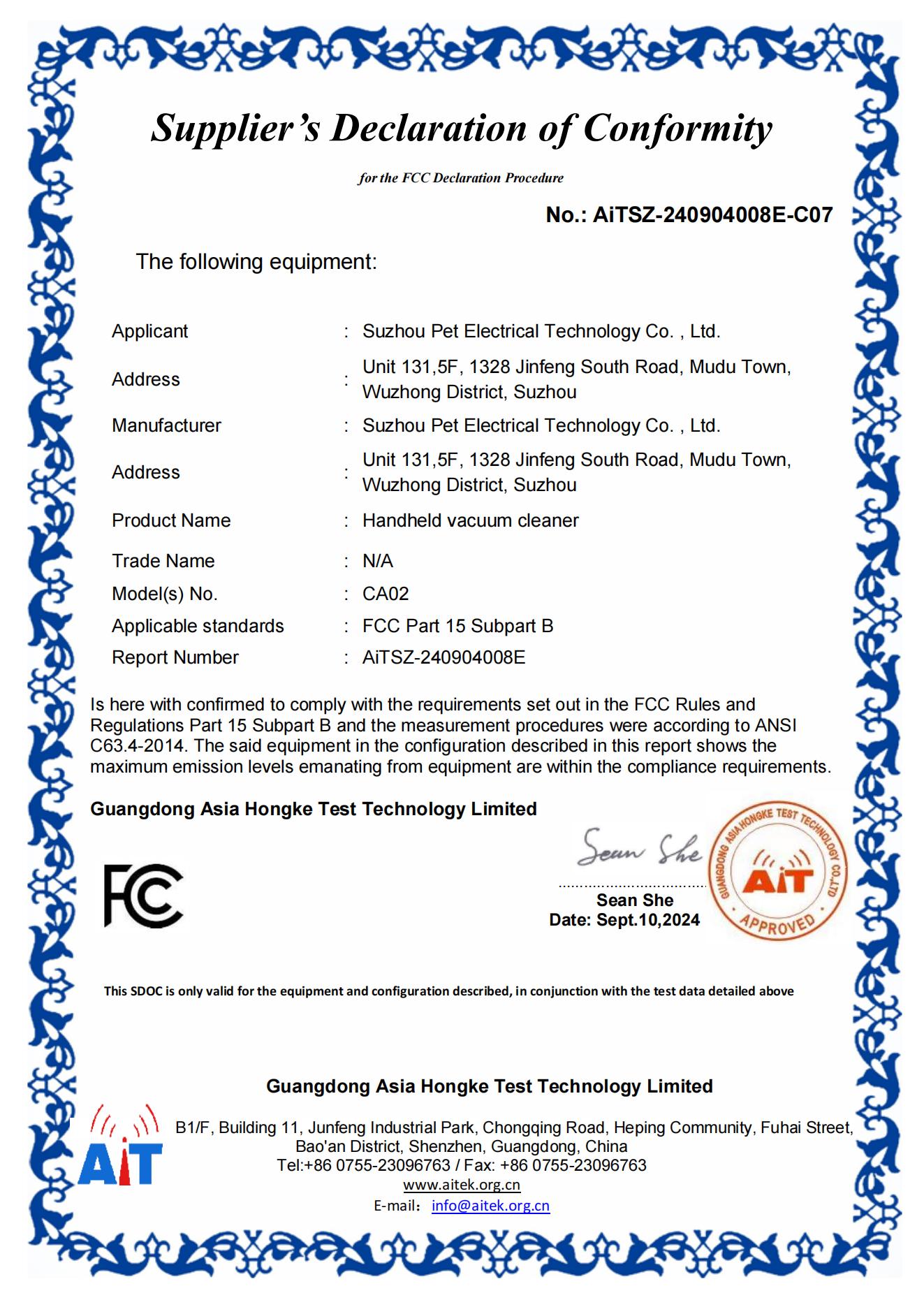

Recently, Suzhou Pet Electronics Technology Co., LTD. (hereinafter referred to as "Suzhou Pet Electronics") has once again achieved good news with its CA02 model handheld vacuum cleaner - the product has successfully passed the relevant tests of the Federal Communications Commission (FCC) of the United States. Obtained FCC Part 15 Subpart B compliance certification and Supplier Declaration of Conformity (SDOC). The test report number is AiTSZ-240904008E, and the compliance certificate number is AITSZ-240904008E-C07. This certification indicates that the CA02 handheld vacuum cleaner fully complies with the US market access standards in terms of electromagnetic radiation control, clearing the key technical obstacles for its entry into the North American market.

The FCC certification Test of the CA02 handheld vacuum cleaner this time was carried out throughout by Guangdong Asia Hongke Test Technology Limited. This laboratory is backed by multiple authoritative qualifications, and the test results have a high degree of credibility. It holds FCC registration number 251906, Canadian Industry Department (IC) registration number 31737, and has been certified by A2LA (American Association for Laboratory Accreditation) (certificate number 7133.01), fully meeting the laboratory capability requirements of ISO/IEC 17025:2017. It ensured the professionalism and accuracy of the testing process and results.

Judging from the core information of the certification documents, the applicant and manufacturer of the CA02 handheld vacuum cleaner are both Suzhou Pet Electronic Technology Co., LTD. The production address is uniformly set as "Unit 131, 5th Floor, No. 1328, Jinfeng South Road, Mudu Town, Wuzhong District, Suzhou City", and the product information is clear and traceable. The product is positioned as a household handheld cleaning device without a specific brand logo. Its core power supply configuration consists of an AC/DC adapter paired with a lithium battery (previously, the EU certification showed battery parameters of 7.4V and 2200mAh), with a rated input power of 70W. This test focuses on verifying its electromagnetic radiation control capability during operation.

This test strictly follows the FCC CFR Title 47 Part 15 Subpart B (Standard for Unintentional Radiators) and ANSI C63.4:2014 (Measurement Method for Radio Noise Emission of Low-voltage Electrical and Electronic Equipment), and is carried out around the two core dimensions of "conducted emission" and "radiated emission". Comprehensively assess the electromagnetic compatibility (EMC) of the product under different working conditions:

The conducted emission test mainly detects the electromagnetic noise released by the product to the power grid through the power line. The test frequency range covers 150kHz-30MHz and must meet the limit requirements stipulated in FCC Part 15.107 (a). During the testing process, the CA02 handheld vacuum cleaner obtained AC 120V/60Hz power supply through the Line Impedance Stabilization Network (LISN), simulated actual usage scenarios, and scanned the electromagnetic emissions of the live wire (Line 1) and the neutral wire (LINE 2) respectively. The maximum emission value was adjusted through the cable to verify the extreme working conditions.

Judging from the test results, the product performs exceptionally well across the entire frequency range In the range of 0.3885MHz-25.2330MHz, the corrected emission value (Reading+Correct Factor) was up to 46.45dBuV (25.2330MHz, QP detection mode), which was much lower than the limit of 60.00dBuV. The minimum margin reached -2.50 dB (25.2330MHz, AVG detection mode), and all frequency points did not exceed the standard requirements, fully demonstrating that its power line conducted noise control capability met the standards.

Radiation emission testing targets the electromagnetic radiation released by products into space and is divided into two frequency bands: below 1000MHz and above 1000MHz. Each band is tested using the 3-meter method (Class B equipment standard), and the radiation levels under both horizontal polarization and vertical polarization conditions are verified simultaneously. During the test, the CA02 handheld vacuum cleaner was placed on a 0.8-meter-high rotating table. The antenna height was adjusted between 1 meter and 4 meters. The rotating table rotated 360 degrees to capture the highest radiation value, ensuring that the test results covered the harshest scenarios.

In the frequency band below 1000MHz (30MHz-1000MHz), the radiated emission value of the product is stable: in the horizontal polarization state, the corrected emission value of the 127.2176MHz frequency band is 25.44dBuV/m, which is lower than the limit of 43.50dBuV/m, with a margin of -18.06 dB. In the vertical polarization state, the emission value in the 54.6428MHz frequency band is 20.36dBuV/m, which is far lower than the limit value of 40.00dBuV/m, with a margin of -19.64 dB. Tests in the frequency band above 1000MHz also meet the requirements of Class B equipment. The radiation level does not exceed the limit standards of 74dBuV/m (peak) and 54dBuV/m (average), fully meeting the FCC's radiation control requirements for household electronic devices.

To ensure the accuracy and representativeness of the test results, the certification process this time was strictly controlled in details such as working condition selection, equipment configuration, and environmental control:

The test team set up four core test modes based on the actual usage scenarios of the CA02 handheld vacuum cleaner: adapter power supply + battery power <1%, adapter power supply + battery power < 50%, adapter power supply + battery power 90%, and standby mode. Through the pre-test, "adapter power supply + battery power < 1%" was selected as the most severe operating condition (EMI test Mode 1). In this mode, the product circuit load is the highest and the electromagnetic emission risk is the greatest. Based on this operating condition, the formal test was carried out to ensure that the certification results can cover the entire life cycle usage scenarios of the product.

The equipment used in the tests has been calibrated regularly and is within the validity period: The conducted emission test adopts the R&S ESCI EMI test receiver and the Kyoritsu KNW-242 line Impedance Stabilization network (LISN); The radiation emission test is equipped with professional devices such as R&S ESR EMI measurement receivers and SCHWARZBECK VULB9160 ultra-wideband test antennas. The last calibration time for all devices is September 8, 2023, and the calibration validity period is until September 7, 2024. Ensure the accuracy of the measurement data. Meanwhile, the test was conducted in a 3.5-meter anechoic chamber and a shielded room. The environmental electromagnetic noise was far below the test limit, avoiding external interference from affecting the results.

During the testing process, all the original data were corrected in multiple dimensions: conducted emissions need to take into account the LISN insertion loss, cable loss, and pulse limiter insertion loss; For radiative emission, the antenna coefficient, cable loss and the gain of the preamplifier need to be superimposed, and finally the corrected actual emission value is obtained. The correction process strictly follows the ANSI C63.4:2014 standard to ensure that there is no deviation in data calculation and the results truly reflect the electromagnetic radiation level of the product.

Let's get in touch.